In this video, Karra demonstrates what a bedroom studio sounds like with and without PSY Acoustics panels.

Mineral wool, renowned for its excellent Noise Reduction Coefficient rating (NRC), is a versatile and high-performance insulation material used extensively in the construction industry. NRC refers to a material’s ability to absorb and reduce sound, making mineral wool an exceptional choice for acoustic insulation in commercial and industrial buildings. Its dense and fibrous structure allows it to effectively dampen noise transmission, creating a quieter and more comfortable indoor environment.

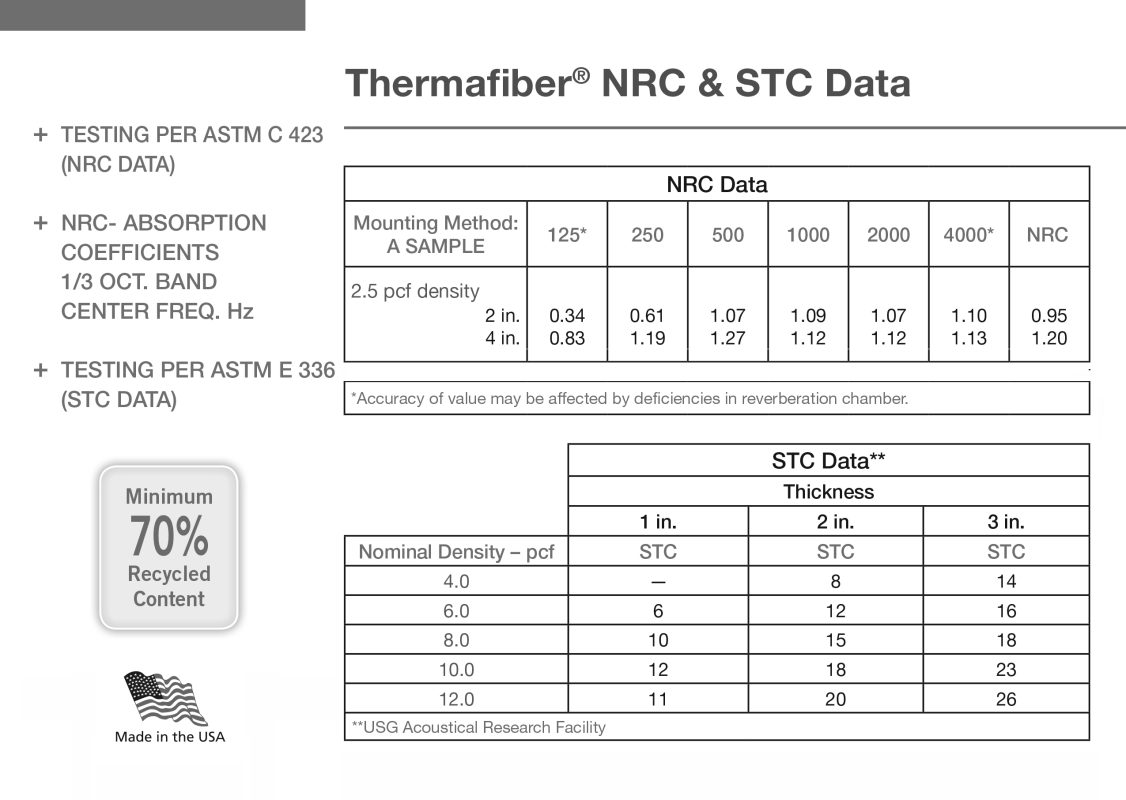

Noise Reduction Coefficients (NRC) are determined through standardized testing procedures to accurately assess acoustic performance. The most common method employed for NRC testing is the ASTM C423 standard, known as the Reverberation Room Method. In this method, a sample of the material under evaluation is placed in a specialized acoustic chamber called a reverberation room. A sound source emits a controlled, broad-spectrum noise signal within the room, and microphones measure the sound levels at various positions.

What is the difference between 2″ thick panels and 4″ thick?

The sonic difference between 2-inch thick and 4-inch thick acoustic panels is substantial and primarily relates to their capacity for sound absorption across different frequency ranges. Generally, 4-inch thick panels provide more extensive absorption capabilities, particularly in lower frequencies. This makes them highly effective in controlling bass frequencies and reducing room resonance, resulting in a more balanced and controlled acoustic environment.

On the other hand, 2-inch thick panels are better suited for managing mid and high-frequency sound reflections, making them valuable for improving speech intelligibility and controlling mid-range echoes. The choice between the two depends on the specific acoustic needs of the space; while 4-inch thick panels excel in studios or home theaters where deep bass control is crucial, 2-inch thick panels may suffice in offices or conference rooms primarily concerned with speech clarity and reducing high-frequency noise.

PSY Acoustics Pro Line

PSY Acoustics Pro Line Portrait Panels (2′ x 4′)

Portrait Panels (2′ x 4′) Landscape Panels (2′ x 4′)

Landscape Panels (2′ x 4′) Square Panels (2′ x 2′ / 3′ x 3′ / 4′ x 4′)

Square Panels (2′ x 2′ / 3′ x 3′ / 4′ x 4′) Cascade Portrait Panels (6′ x 4′)

Cascade Portrait Panels (6′ x 4′) Ceiling Clouds (72″ x 40″ x 4″)

Ceiling Clouds (72″ x 40″ x 4″) Custom Panels

Custom Panels Prints (2′ x 4′) – Fabric Only

Prints (2′ x 4′) – Fabric Only Au5

Au5 Ilio

Ilio Jordan Rudess

Jordan Rudess Justin Vibes

Justin Vibes Kali Audio

Kali Audio Karra

Karra Libra Rising Music

Libra Rising Music MIDIhead

MIDIhead Neon Vines

Neon Vines School Of Rock

School Of Rock Tritonal

Tritonal 2k Games

2k Games Andy Lunique

Andy Lunique Bungie

Bungie Burke Black

Burke Black Delrith

Delrith Epic Games

Epic Games FG Tee V

FG Tee V Fightin’ Cowboy

Fightin’ Cowboy Gearbox Software

Gearbox Software Imperial Hal

Imperial Hal Oddworld Inhabitants

Oddworld Inhabitants Probably Monsters

Probably Monsters Striking Distance Studios

Striking Distance Studios Benn Jordan

Benn Jordan Chef PK

Chef PK Full Court Pumps

Full Court Pumps Priyon Joni

Priyon Joni Red Means Recording

Red Means Recording Reid Stefan

Reid Stefan Stacey Roy

Stacey Roy Venus Theory

Venus Theory